1 Piece

Dongtai Yaoqiang Welding Facture Co., Ltd.

Welding Machine,Pipe Welding Machine,Steel Structure Beam Welding Equipment,CNC Cutting Machine,Wind Tower Production Line Equipment

Welding Machine,Pipe Welding Machine,Steel Structure Beam Welding Equipment,CNC Cutting Machine,Wind Tower Production Line Equipment

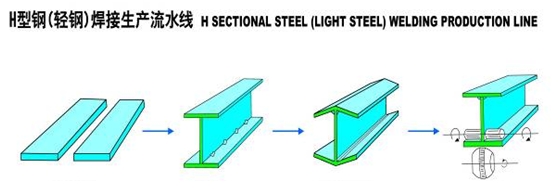

> Industrial Equipment & Components > Welding & Solder > Welder > Assembling-Standing Machine for Steel H Beam Production Line 1 Piece

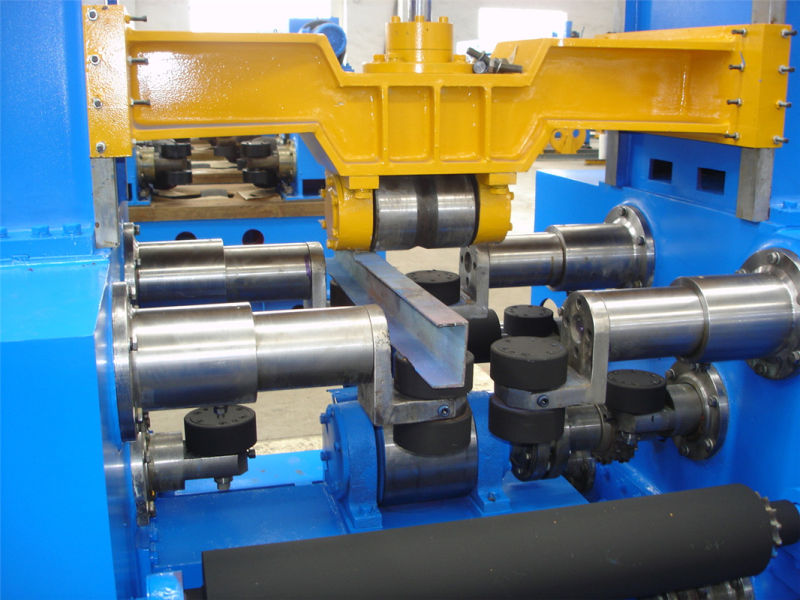

| Model | Z15 | Z18 | Z20 |

| web height mm | 200-1500 | 200-1800 | 200-2000 |

| web thickness mm | 6-32 | ||

| web length mm | 4000-15000 | ||

| flange width mm | 200-800 | ||

| flange thickness mm | 6-40 | ||

| assembly speed mm/min | 500-6000 | ||

| feeding table roller mm | 2600×2 | ||

| output table roller mm | 2600×2 | ||

| centralized way | hydraulic link mechanism clamp, centralize and weld in the middle automaticly | ||

| speed control | imported AC frequency adjustor stepless adjust | ||

| input volumn | 16KVA exclude wellding power | ||

| welding system | 2 sets of CO2 protecting welding machine | ||

Welding Machine, Pipe Welding Machine, CNC Cutting Machine manufacturer / supplier in China, offering H-Beam Surface Cleaning Equipment, Gd-20 Type Mi...

-Secure payments

-Guaranteed refunds

-Escrow protection on every order

-Guaranteed delivery of goods