activated carbon making machines1)Rotary kiln for activated carbon

2)with S.S surface and fire bricks inside

3)around 3 ton per day

Activated carbon machine/kiln:

Activated carbon machine/kiln:1. Rotary kiln

1. The rotary kiln is made up of a large, rotating cylindrical tube which is lined with fireclay bricks. The rotary kiln slopes slightly so that the discharge end is lower than the material feeding end. The material goes slowly along with rotation to the discharge end. It's fully activated when it comes out of the discharging mouth.

2. Working principle of the rotary kiln :

The material is conveyed into the rotary kiln by a measurable feeder continuously. Driven by motor and gearbox, the rotary kiln rotates steadily. The carbonized material inside the kiln is turned along with the rotation of kiln. Steam is supplied into the rotary kiln by steam duct. The carbonized material is activated by hot steam at high temperature. Because the rotary is sloping slight, the material is going slowly down towards the discharging end. When the material comes out, it's completely activated.

Packing information:

nude packing or be negotiable according the order

Activation process of activated carbonNowadays, activated carbon is in general made from coconut shell, apricot shell, walnut shell, hawthorn shell, palm shell and wood charcoal. This production line consists of PLC automatic control system, hopper, elevator, cooling system, incinerator, boiler, blower and dust removing system.

Prerequisite of activation: pellet size>2mm, moisture<15%. At first, convey carbonized material up to the top hopper by elevator, then feed the material to rotary kiln steadily by feeder controlled by inverter. At this time, temperature inner the rotary kiln is above 800ºC. Start blower to supply air into the rotary kiln. The charcoal react with hot steam and produce a large amount of heat. Therefore the temperature rises up to 900-1050 ºC momentarily. From this moment on, the contact time of the material of hot steam is activation time. This period is variable depending on temperature and amount of oxygen between 25-40 minutes, that is the material is going forward at a speed of 6m per hour along the rotation of the rotary kiln. Then passing the cooling section of the rotary kiln, going into the discharging pipe, at this stage, activated carbon temperature is down to 200ºC, finally, the activated carbon is discharge from the rotary kiln and drops into cooling kiln. After 3 minutes cooling, the activated carbon will be chilled to room temperature 30-40ºC, being ready for packing. Function of incinerator: pre-heat of boiler, settling of dust, sustain hot steam supply when the kiln is shut off to avoid pipe broken as result of frozen water, burn the fume and reduce black smoke and make the most energy of the smoke. The incinerator is followed by boiler which using afterheat to produce hot steam and activate the charcoal. Blower suck the hot air to boiler and send the smoke to bag filter. Finally the smoke meets the emission standard.Methylene Blue >10, Iodine Number: 1000mg/g, Output capacity: 3 tons

Methylene Blue >10, Iodine Number: 1100mg/g, Output capacity: 2.5 tons The highest Iodine value: 1200~1300mg/g

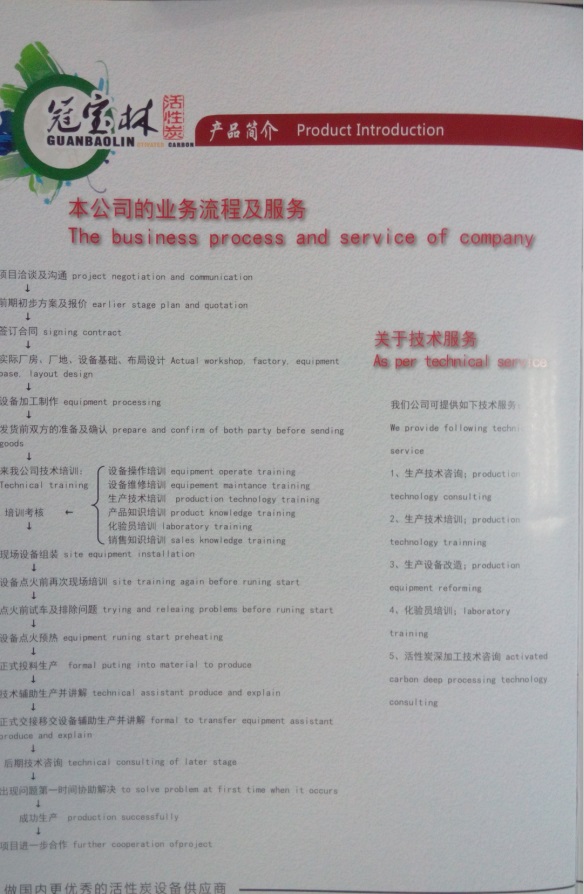

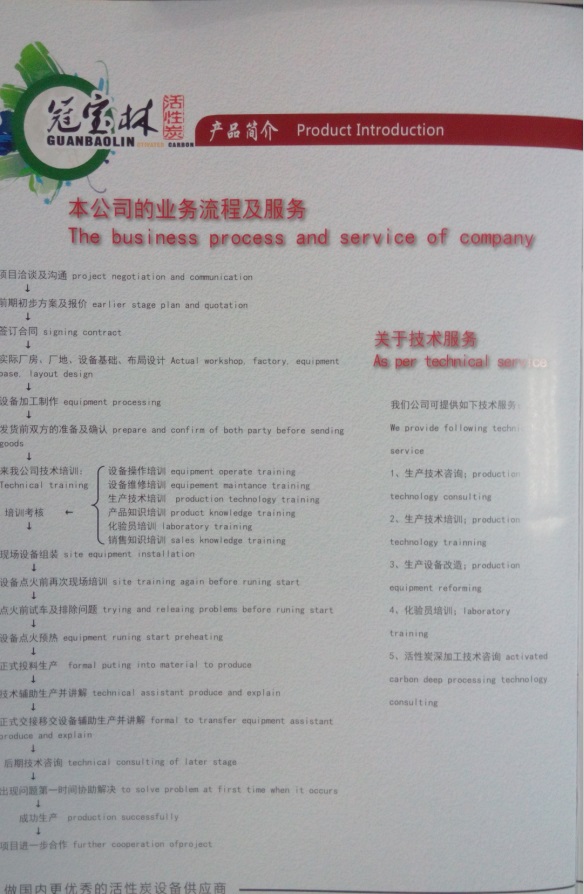

Qingdao Guanbaolin equipment technology Co.,Ltd, in connection with Qingdao Guanbaolin Activated carbon Co.,Ltd, is a professional manufacturer and supplier of activated carbon production line, activated carbon adsorption equipment and activated carbon production& application technology. With a total investment 15million yuan and registered capital 10.8million yuan, The company covers an area of 20000 square meters. Strength and quality are inherited and enhanced from Qingdao Guanbaolin activated carbon Co.,Ltd. Warmly welcome you to visit us and do business.

Qingdao Guanbaolin equipment technology Co.,Ltd, located in Jiaobei International industrial zone of Qingdao city, produces activated carbon production line featuring high automation, stability and reliability. We have another company Qingdao Guanbaolin activated carbon Co.,Ltd, Using our own production line , has been producing activated carbon for 7 years. Our machine is proven to be of high quality. And we are always looking to improve to perfection. We attach great importance to reputation, quality and service. Turn-key project is one of our advantages. With our quality machine, wide-ranging and professional training, the project will justify your outlays in short time.

How work toghether? Why choose us?

Why choose us?- The production line is easy to install and disassemble, requiring short construction time.

- Easy operation, low cost of start-up and shutdown,

- Very low maintenance cost.

- Long service time, low equipment cost

- Simple repair, no need of shutdown for repair;

- Punctual delivery, high quality guarantee the interests of buyers

- Integrated training provided with buyers includes equipment, technology, production, laboratory tests, deep processing, sales.

- Iodine value is adjustable from 1100 to 1400

- Undertake installation/ commissioning/ technological service at abroad.

- We have activated carbon production factory at work, enabling us to accumulate abundant experience. Welcome to visit us and inspect our machinery and production. Our technology, experience and equipment will make us your optimum choice.