1 Piece

Guizhou Pilot Precision Instruments Manufacturing Co., Ltd.

Flowmeter

Flowmeter

> Instruments & Meters > Meter for Liquid & Gas > Flow Meter > Open Channel Ultrasonic Flow Meter 1 Piece

1.Repeatability better than 0.2%.accuracy:better than 1%

2.Display:2*10 backlit LCD(Chinese and English optional)

3.Operating power: AC 85-264V or isolation DC 8-36VDC

4.Transducer: clamp-on type,insertion type,in-line type

5.Protection:mainframe:IP65, transducer:IP:65

6.Signal output: one channel standard isolation RS485 output;

7.One channel isolation 4-20mA or 0-20mA active output;

8.One channel OCT output(programmed between the pulse width(6-1000ms),default before leaving factory (200ms)

9.One channel isolation relay output,with positive ,negative,net accumulation pulses and different alarm signals.

10.Input:two channel three wire system PT100 platinum resistor input loop,to make heat meter has the function of displaying heat quantity. Three channel 4-20mA input optional,accuracy:0.1%,has the ability to 11.input the signals of pressure, liquid level, temperature and so on.it can display calory by heat module.

Technical Parameters

| Accuracy | 1% |

| Repeatability | 0.2% |

| Measurement period | 500m/s(twice every second) |

| Power | version 10/version15:85-264VAC/24VDC |

| Flow rate range | 0~±32m/s(resolution ratio 0.001m/s) |

| Display | 2×10 backlight LCD |

| Operation | 4×4 soft contact keyboards |

| Signa input | 5 way 4-20mA input,accuracy 0.1% |

| Signal output | 1 way isolation 4-20mA or 0-20mA output 1 way isolation can be programmable OCT,used for output plus,minus net cumulative pulse and all kinds of alarm signal 1 way relay can output plus,minus net cumulative pulse and all kinds of alarm signal |

| Communication protocol | FUJI (version 7) MODBUS |

| IP grade | IP65 |

| Explosion-proof grade | EXDIIBT4 |

| Case material | Die-casting aluminum |

Ultrasonic flow meter

| Technical Parameters | Standard insert type B | Water meter insert type B | Stretched insert type B |

| Suitable main engine | Integrated,split type,transmit type,flow rate model | Integrated,split type,transmit type,flow rate model | |

| Suitable pipe diameter | >DN80 | ||

| Material | Ball valve and probe :Stainless steel 316L Ball valve plate:general carbon stell(stainless steel optional) | ||

| Working frequency | 1HZ | ||

| Connecting way | V,Z,N | ||

| Suitable temp | -40~160ºC | ||

| Open hole size | Φ19mm | ||

| Pressure grade | 1.6MPa(installation pressure>0.8MPa) | ||

| IP Grade | IP68 (water proofed,water depth<3 meter) | ||

| Length | 186mm | 228mm | |

| Water,sea water,sewage,alcohol,all kinds of oil | |||

| Medium | |||

| Medium turbidity | <10000ppm | ||

| Single cable | Type SEYV75-2,four-core special shield wire,can be stretched to 500 meters | ||

Company Information

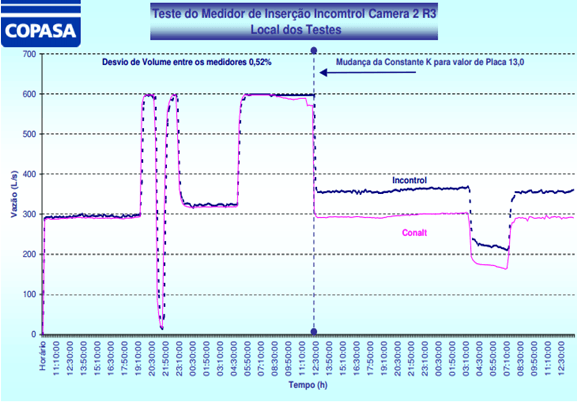

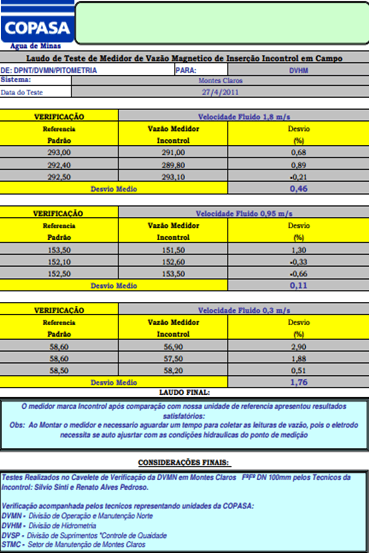

Incontrol Precision Instrument CO., LTD, a joint venture established by Pilot Group and Brazil Incontrol, is a technical service enterprise offering professional technical solutions to flow and an agency for Incontrol flowmeters in China.

As an important partner of this joint venture, Incontrol locates in Sao Paulo, Brazil's largest city. It has owned a history of nearly 40 years in R&D, manufacturing and marketing of flowmeters since 1974. At present, Incontrol is the largest flowmeter enterprise in South America, independent in designing converters. Furthermore, the biggest calibration laboratory and production line have been set up,and already obtained the related certifications, such as ISO9001,ISO17025,Inmetro,etc.

The electromagnetic flowmeters which we sell, are widely used to control the flow of fluid in the industries of tap water and sewage treatment, petrochemical, food and beverage, paper-making, pharmaceutical,metallurgical manufacturing, textile and so on.

As a new comer in China, our company will provide the most cost-effective flowmeter products with the greatest enthusiasm and the most delicate services to our customers.At present, we have set up marketing and technical service center in Shenzhen, China, among which are 10 domestic and international high-quality sales staff and up to 20 professional technicians and engineers. What's more, our company has after-sales hot-line in Shanghai and Shenzhen in order to provide round-the-clock technical support and services for the customers.

In China, to achieve the goal of providing better products to customers, and gradually improving the local strength of technology research and development and service, we have established a new joint venture factory in Guizhou, China. In the future, our company will expand production and supply capacity of the product synchronously.

Hope that through the accurate, effective and cost-effective products and timely and thoughtful technical services support, we will be partners and develop together.

The VMI series of flowmeter is an excellent way to measure flow in big diameter pipes with a low cost. The size of the pipe could be from DN150 to DN2000. It is normally utilized in water impound, drink water distribution, sewage, electric power plant and so on.

Depends on the condition of the pipe the VMI sensor can be installed without process shutdown. To remove the sensor to install at another location or for maintenance purpose it also no need to stop the process installation or removal can be done without line depressurization.

Two version of VMI installation are offered -- one is fixed style and the other is adjustable. The fixed is mounted to the line by mean of flange connection and the adjustable is mounted to the pipe utilizing a valve, depending of the size of pipe the insertion length is changed, normally it is mounted at 1/8 of internal diameter of the pipe. There are three standard sensor lengths to support from DN150 to DN2000 pipes.

FAQ

1. Working theory

The measuring principle of the electromagnetic flow meter is based on Faraday's Law, as a conductive fluid with velocity V passes through the magnetic field B generated by the coils, a voltage E(emf) is developed across the electrode installed vertically at 90 degree from the magnetic field and the velocity.

2. How to choose the meter size and model?

It is very important to select right meter model in flow rate measurement. Many relative information point out that meter fault happened in application, two thirds is due to wrong selection meter model and installation. Right selection of meter model should be according to the conditions as follows:

Parameters collection:

Composition, density, conductivity of the fluid to be measured

Maximum, minimum & operating flow rate

Temperature Range

The fluid must be conductive and its conductivity>5μs/cm

2.1 Measuring medium?

The medium must be strictly conductive; as long as the fluid conductivity is more than 5µ/cm we can use magnetic flow meter for the measurement. So non-conductive gas, steam, vapor, fuel, acetone etc. can't be measured by electromagnetic flow meter. This should be offered by customers for us to choose the electrode and line materials.

2.2 Diameter?

The instrument diameter is not always the same as pipeline size, depending on flow rate.

Generally, if the velocity is in the range of 0.3~15m/s, the diameter is same as pipeline size; if less than 0.3m/s, we should consider to shrink the pipe to raise the velocity; the flow meter diameter is normally less than pipeline size in order to ensure the accuracy. There are three ways to get the diameter information: customer specified; according to the maximum or operating flow rate and choose the diameter in the Flow-Diameter Comparison Table; ask the customer about the flow rate of the pump, then refer to the flow rate table.

2.3 Integrated or Separate?

Integrated type: if the working condition is good, we generally choose the integrated type, it means the sensor and converter is integrated.

Separate type: sensor and converter are installed in different places under the following conditions:

1) The ambient temperature or the converter surface raying temperature is more than 60°c

2) The flow meter is installed in the high place or not convenient to see the local display

3) Strong pipeline vibration

4) Strong corrosive or abrasive medium

Remark: when we choose separate type magnetic flow meter, the separation distance between the sensor and converter should be less than 100m, and the converter is wall-mounted installation type.

2.4 Electrode material?

We should take the measuring medium corrosion into consideration before we decide electrode material. Generally electrodes include 316L, HB, HC, titanium, tantalum, platinum etc.

2.5 Line material?

We should consider medium corrosion, abrasiveness and temperature before choosing the lining material, generally including rubber(ebonite, neoprene, polyurethane) and Fluor plastic(F4 or PTFE, F46 or FEP and PFA).

2.6 Pressure?

Normally the pressure parameter is specified by the customers, general conditions are 1.0, 1.6 or 2.0 MPa.

2.7 Working temperature?

The working temperature is the key to decide if the flow meter is integrated or separated. It is suggested to choose the separate type if it is more than 60ºC.

2.8 Liner material?

Nonmetal pipeline must use grounding electrode or grounding ring.

2.9 Output signal

4-20mA standard configuration, only with instant flow rate display if connected with computer

Frequency output standard configuration, 0-1000Hz is corresponding to the percentage of the flow rate

Pulse output standard configuration, with accumulative flow rate display and trade settlement measurement

2.10 Power supply?

220 V AC, 24V DC or specified by customers.

2.11 Flange?

Different country has different flange standards, generally used are GB, ANSI, JIS, BS4504, DIN, etc.

3. What is the application field of electromagnetic flow meter?

VM series electromagnetic flow meter is suitable to measure volumetric flow rate of the conductive liquid in the full closed pipe, e.g. clean and row water, sewage, acid, alkali, salt, slurry, slag, paper and pulp, dehydrated food, beverage and so on.

4.Features of our products

Reliable and accurate measurement in most of the flow measurement application

Easy to select, install and operate

CIP/SIP cleaning possible

Robust in operation

Chemically resistant to acids and alkalis

Temperature up to 150°c

Setting via frontal keyboard or communication, accuracy better than ±0.3%

Protection grade can be IP67 and IP68

Body sealed by welding to protect against humidity

Standard process connections (GB, ANSI, DIN, JIS, NBR)

Hygienic connection for food, pharmaceutical, beverage

Compact or remote converter

Galvanic and chemical corrosion resistant and submersion painting protection

Electronics indicator totalizes in volume or mass

Bidirectional flow totalizer, batch control option

Universal converter, it works with any manufacturer electronic module

Flow converter for almost all applications

Diagnostic functions

Flexible with customized solutions

Non volatile memory

Password protection

Output relays for alarms or control (pumps, valves)

Wireless data transmission

5.Calibration

Our Flowmeter Calibration Lab uses the methods of Weighing and Standard Meters, as well

as the Traceable Principle regulated by the international Flow Calibration System. Thus, our flow metes can be applied in the process of storage and production.

The max flow volume calibrated can reach 6000m³/hour and the size can reach DN1200. Our lab has independent production lines for flow meters, where 3 flow meters can be calibrated at the same time. All flow meters manufactured by us have passed strict calibration test procedures before delivering to customers to assure the high precision, best performance and stability of measurement.

All our flow meters are calibrated by the ISO4185, and our lab is also controlled by ISO17025.

6.Why choose us?

Our products not only have the advantages like common ones, such as not affected by the changing of temperature, pressure, viscosity, and density of fluid; no pressure loss because of the absence of resistance inside the pipe; no moving parts; longer operating life and so on, they also possess the advantages of good performance, high accuracy, user-friendly installation. What's more, the greatest advantage is that converters through our independent research and development can replace any other company's.

The flowmeter converter PRO and incoMag series apply latest SMT technology using the most advanced technology in flow measurement.

Electromagnetic flow meters can be used in any industry to measure liquids (with or without solids content), such as pulps, pastes and other mediums that have a specific minimum of electric conductivity.

Superior electronic converters have a satisfactory measuring effect - reliable and repeatable even under complex conditions, while manufacturing quality guarantees years of trouble-free use.

7.Certificates and some user report

Packaging & Shipping

Package:

Standard carton box or wooden case

Shipping:

Small order: Courier (UPS, FEDEX, DHL etc.)

Large order: Sea or Air service

Origin city: Guizhou, China

PCB Board, Flow Meter, Electromagnetic Flow Meter manufacturer / supplier in China, offering Dual Channel Ultrasonic Water Meter with Built in Battery...

-Secure payments

-Guaranteed refunds

-Escrow protection on every order

-Guaranteed delivery of goods