1+

US $18000

Plastic recycling machine, extruder, auxiliary machine

> Manufacturing & Processing Machinery > Plastic Machinery > Plastic Granulator > High Efficiency Recycling Granulator/Plastic Recycling Machine/PP/PE Pelletizing Line 1+

US $18000

Machine Application:

Woven bag, printed LDPE film, film (rolls, loose, bundled) waste agriculture film, foamed plastics (EPS) and raffia

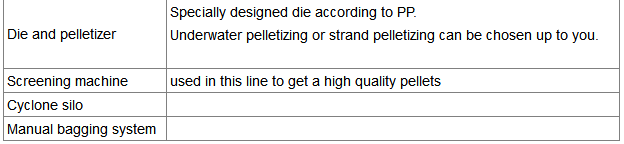

Machine General introduction:

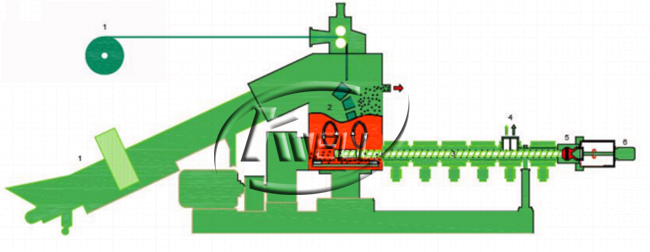

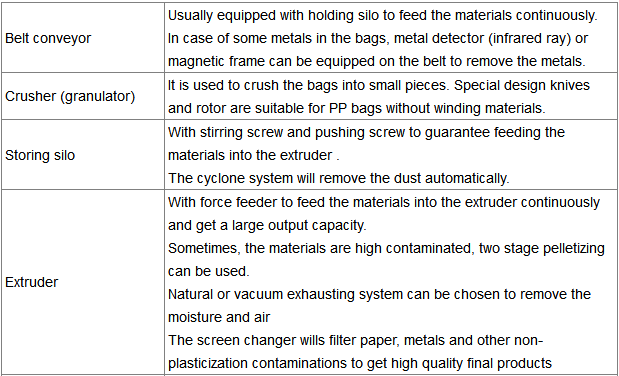

From shredding compactor, the material is transported directly into the extruder by a belt conveyor without being precut or compressed. The rate of material feeding is controlled automatically by the current of the extruder motor and main extruder screw rotating speed. This design will keep material with balance feeding, and protect material from blocking and melting in the shredding compactor.

Degassing parts: natural degassing/ vacuum degassing

Melting plastic is filtered by a continuous melt filter (plate hydraulic screen filter, double volume screen changer) available with or without back-flushing system. According to material type, the pelletizing way can be equipped with a water ring, strand or underwater pelletizing system.

Machine Technical Parameter:

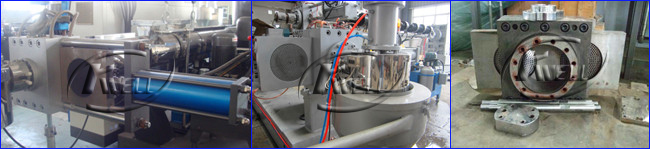

Machine Detail photos as a reference:

Machine packing details:

After-sale:

1. Provide with installation, commissioning and training

2. Register and record customer information

3. Offer spare parts

4. Provide with necessary technical support for new application

5. Visit customer regularly and correct information

Why choose us:

1. Lower investment cost for a high quality and durable machine;

2. Low energy consumption with high production output;

3. Overseas installation and training are available;

4. Machine warranty with spares in stocking and in-time delivery;

5. Fast machine delivery and installation: KWELL produces on an average of 10 sets of plastic machines per month and can deliver the machine faster than most manufacturers. The regular delivery time of an KWELL recycling machine is 40-60 days.

Please convenient yourselves by me !!

Kwell machinery is a leading manufacturer of plastic recycling and extrusion machinery in China. Our company is located in Zhangjiagang City, Eastern ...

-Secure payments

-Guaranteed refunds

-Escrow protection on every order

-Guaranteed delivery of goods