1

Basic Info

- Place of Origin:

- Brand Name:

- Model Number:

- Material:

- Thickness:

- Size:

- Color:

- Application:

- Certificate:

- Feature:

- Density:

- Surface:

- Usage:

Product Description

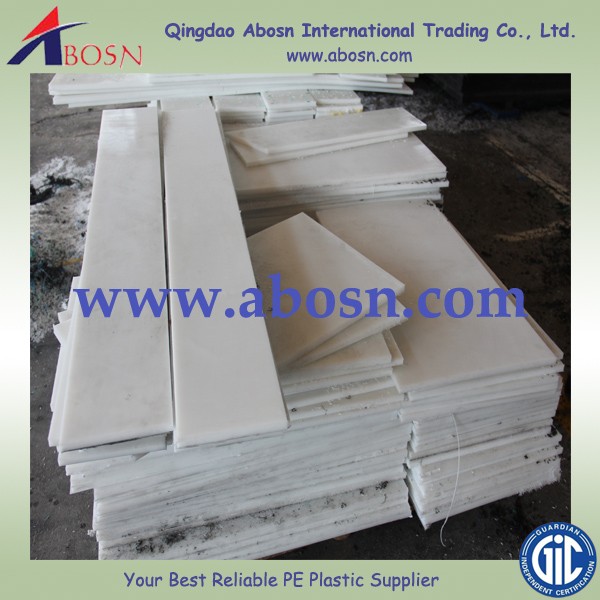

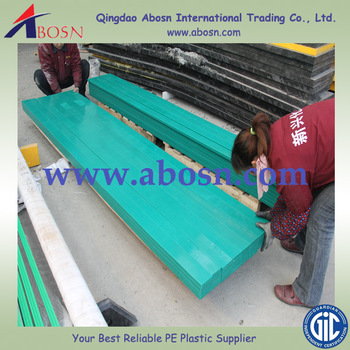

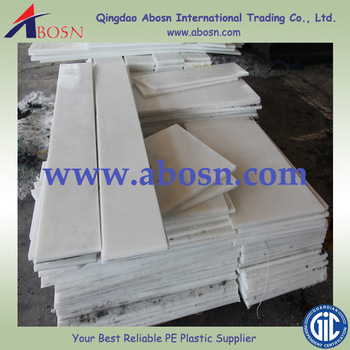

UHMWPE/HDPE wear strips

Why choose uhmwpe&hdpe wear resistance strip and anti-wear block for various machine ?

UHMW-PE(Ultra high Molecular Weight Polyethylene )is a thermoplastic engineering plastic with the average molecular weight more than 9.0 million. (PE only has the molecular weight between twenty to two hundred thousand.) This kind of material with five top performance of high-wear-resistance, good-chemical resistance, low-temperature resistance, self-lubrication and high-impact resistance, which is regarded as a “surprised” engineering plastic of excellent comprehensive capacity and competitive price.

| Property of UHMWPE strip |

| ultra-high-molecular-weight polyethylene (UHMWPE, UHMW)

is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene, (HMPE), or high performance polyethylene (HPPE), it has extremely long chains, with a molecular mass usually between 2 and 6 million u.The longer chain serves to transfer load more effectively to the polymer backbone by strengthening inter molecular interactions.

Property of UHMWPE strip

Its coefficient of friction is significantly lower than that of nylon and acetal; UHMWPE strip has better abrasion resistance than PTFE, 15 times more than carbon steel. With the highest impact strength of any thermoplastic presently made; UHMWPE strip is odorless, tasteless, and nontoxic; It is highly resistant to corrosive chemicals except oxidizing acids; Has extremely low moisture absorption and a very low coefficient of friction; Is self-lubricating; this property rank the second lower than PTFE. |

Uhmwpe&hdpe wear resistance strip and anti-wear block for various machine:

1. Very high-wear resistance, seven times wear resistance than steel, four times than PTFE

2. Very high anti-impact resistance, two times impact resistance than PC, five times than ABS.

3. Good self-lubrication, the same as PTFE, better than steel and brass appended lubricating oil.

4. Good anti-corrosion resistance, it has very stable chemicals property and can endure the corrosion of all kinds of corrosive medium and organic solvent in certain rang of temperature and humidity.

5. Very high-inadhesion resistance, the surface of product hardly affixes other material.

6. Very high-impact resistance, ten times impact resistance than PA66, eight times than PTFE.

7. Good low temperature resistance, in liquefied nitrogen (- 196°C), it still has the prolongation.

few other materials can reach to this performance.

8. Non-toxic and clean property, UHMW-PE, which is the material that Food and Drug Administration (FDA) and United States Department of Agriculture (ASDA) permit to apply in food and medicine fields.

1. More than 30 years' professional manufacturing experience with own factory

2. Virgin 100% material produced, high quality with good surface and color make ensured

3. GB/T 19001-2008 ; ISO 9001:208 inspection

4. Competitive price, In stock, Fast delivery, and Excellent service.

5. OEM Special character is available: According to different requirements and different application.

Color, size, shape and special specifications can be customized, such as anti-UV, anti-static and so on.

Shandong Ningjin Xinxing Chemical Co.,Ltd. is one of the largest Engineering Plastic products manufacture in China.All the stuff in our company are dedicated to producing satisfying products and developing new products for our customer. | |

Sheet ,HDPE Sheet ,PP Sheet ,Urethane Sheet ,PVC sheet and other Engineering plastic products. | |

Sold By

Qingdao Abosn was located in Qingdao, the third-largest port city in China; with convenient traffic and developed imports and exports. As the qingdao...

Contact Seller

MessageBuyer Protection

-Secure payments

-Guaranteed refunds

-Escrow protection on every order

-Guaranteed delivery of goods

Product Groups

- Ungrouped

- UHMWPE Fender facing pads

- UHMWPE Liner sheet

- UHMWPE Wear resisting strip

- UHMWPE Dewatering elements

- UHMWPE Dock bumper

- Crane Outrigger Pads

- UHMWPE Chain guides

- UHMWPE Rod

- PTFE Sheet

- UHMWPE Sheet

- Ground protection mat

- PP sheet

- Conveyor impact bar

- Cutting Board

- Ice Rink System

- PVC

- Other UHMWPE machined parts

- HDPE Sheet

- More

鲁公网安备37079102000201号

鲁公网安备37079102000201号