1

Basic Info

- Place of Origin:

- Brand Name:

- Model Number:

- Material:

- Thickness:

- Size:

- Product:

- Density:

- Shape:

- Certification:

- Surface:

- Color:

- water absorption:

- low friction:

Product Description

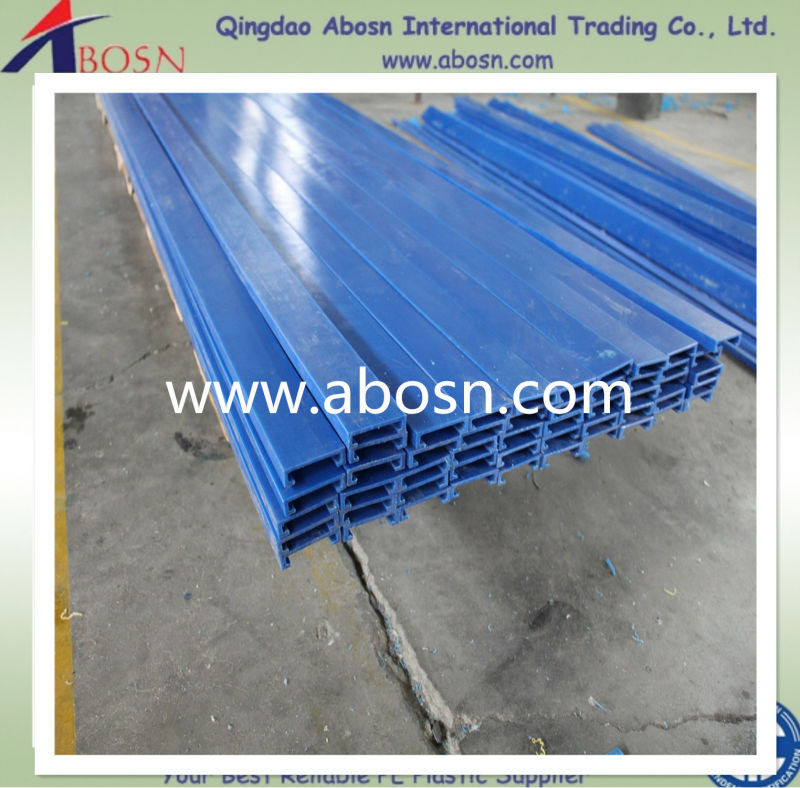

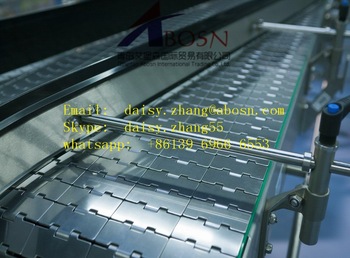

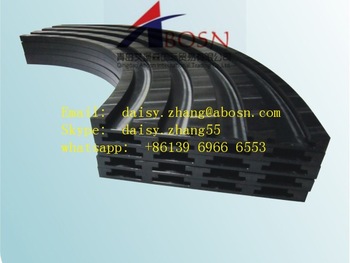

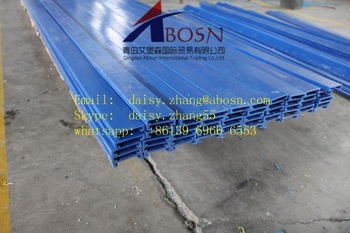

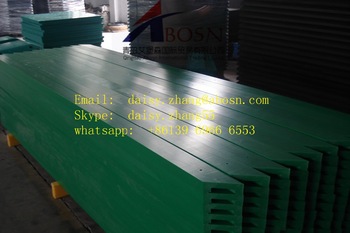

Wear resistance UHMWPE roller chain guide

Brief Introduction of UHMWPE:

UHMWPE extremely high molecular weight with its superior performance, and belongs to the moderate price, good performance of thermoplastic engineering plastic, it's almost focus on the advantages of all kinds of plastic, with ordinary polyethylene and other engineering plastics incomparable abrasion resistance, impact resistance, self-lubrication, corrosion resistance, absorb the impact energy, low temperature resistance, health, non-toxic, difficult to adhesion, small water absorption, density and so on comprehensive performance. In fact, it is not a pure polymer materials with so many outstanding performance

Wear resistance

The wear resistance of UHMWPE in the crown of plastic and exceed certain metals, figure 1 for UHMWPE wear resistance compared with other materials. As can be seen from the figure 1, compared with the other engineering plastics, UHMWPE mortar abrasion index is only 1/5 of PA66, HEPE and PVC 1/10; Compared with the metal, is 1/7 of the carbon steel, brass 1/27. Such high wear resistance, so that with general plastic abrasion experiment method to test its wear-resisting degree, and designed a kind of mortar abrasion test device. UHMWPE wear resistance is proportional to the molecular weight, molecular weight is higher, its wear resistance, the better.

Resistance to impact

The impact strength of UHMWPE, are among the best in all engineering plastics, figure 2, compared with other engineering plastics, the impact strength of UHMWPE can be seen from the figure 2, the impact strength of UHMWPE is about 2 times impact resistance of the PC, ABS five times, POM and PBTP more than 10 times. The resistance to impact so high that usually impact test method is difficult to make the fracture damage. The impact strength increase with the increase of molecular weight, reach maximum when the molecular weight of 1.5 million, and then gradually decreases with the molecular weight of continue to rise. Worth pointing out is that in liquid nitrogen (195 ℃) can maintain excellent impact strength, this feature is no other plastic. In addition, it's on the repeated impact surface hardness is higher.

Self lubrication

UHMWPE has a very low friction factor (0.05 ~ 0.11), so the excellent self-lubrication. Table 1 for UHMWPE compared with other engineering plastic friction factor. Can be seen from table 1, UHMWPE dynamic it friction factor under the condition of water lubricated PA66 and POM 1/2, under the condition of no lubrication is second only to the lubricity of the best in the plastic polytetrafluoroethylene (PTFE); When it is in the form of sliding or rotating job, lubricity than steel and brass after add lubricating oil. Therefore, in the field of tribology UHMWPE is regarded as a friction material cost/performance is very ideal.

Chemical resistance

UHMWPE has excellent resistance to chemicals, except strong oxidizing acid in certain temperature and the concentration range can all kinds of corrosive medium (acid), alkali, salt and organic medium (except tea solvent). In 20 ℃ and 80 ℃ for 80 kinds of organic solvent impregnated 30 d, appearance without any abnormal phenomenon, and other physical properties are almost no change.

Shock absorbing

UHMWPE has excellent impact energy absorption, shock absorbing value the highest in all plastic, damping and noise performance is very good, it has excellent sound effects.

Low temperature resistance

UHMWPE has excellent resistance to low temperature, the liquid helium temperature (269 ℃) still has the ductility, resistance to low temperature and thus can be used for nuclear industry parts.

Health non-toxic

UHMWPE health non-toxic, can be used in contact with the food and drug.

Not sticky

UHMWPE surface adsorption ability is very weak, not in its ability to resist adhesive character after plastic viscosity best PTFE, thus products surface with other material is not easy to stick.

Small water imbibition

UHMWPE bibulous rate is low; Generally less than 0.01%, only 1% of the PA66, thus generally don't have to dry processing before processing.

The density

UHMWPE and other engineering plastic density is relatively low.

The tensile strength

Because the UHMWPE has the stretching orientation and essential structural features, so there are unmatched high tensile strength, so by gel spinning method, high elastic modulus and strength of the fiber, the tensile strength up to 3 ~ 3.5 GPa, tensile modulus of elasticity is as high as 100 ~ 125 GPa; Of commercialization of fiber strength is so far the highest of all fiber, 4 times larger than the carbon fiber, 10 times greater than steel, 50% larger than the aramid fibers.

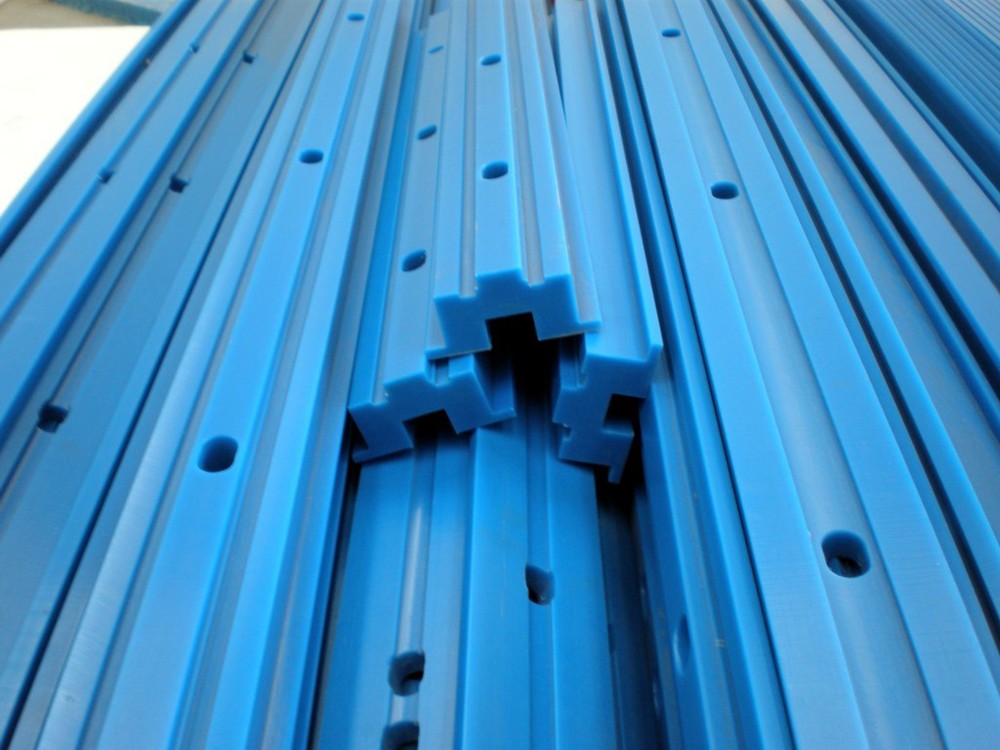

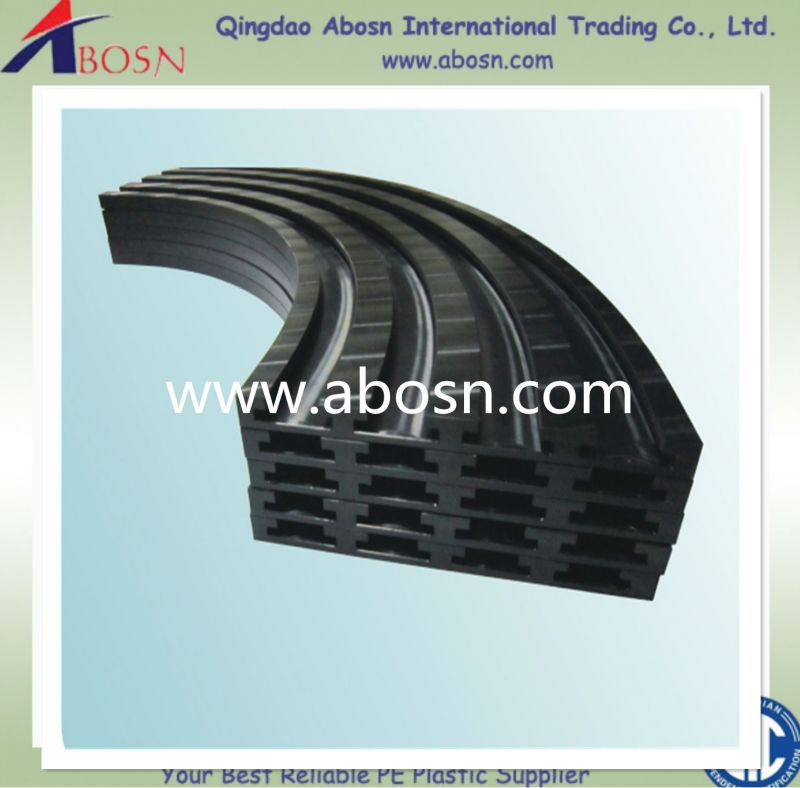

Our UHMWPE Chain Guide Characters:

1.very flat on the surface.

2.The color is pure and any color can be made by us.

3.We can give you an accurate size of UHMWPE chain guide with advanced machine.

4.Different shaped UHMWPE chain guide also can be made by us like bending sheet.

5.According to different requirements with different application, special specifications can be customized.

Advantages of UHMWPE chain guide:

1.Extremely high impact strength

2.Excellent wear and abrasion resistance

3.Optimal sliding properties

4.Dimensional stability

5.Energy absorption capacity at high loading rates

6.Resistance against fatigue

7.Water repellent

8.Good chemical resistance

9.Excellent electrical and dielectric properties

10.Physiologically harmless

Specialties

| Mode of Forming | Extrusion, pressing |

| Features | Easy to clean |

| Certification | |

| Surface | Plain |

| Standard Colors | |

| Characteristics | |

| Applications | 1. Chain guides 2. Wear curves 3. Bearing surface 4. Belt guides 5. Textile Industry 6. Chemical Industry 7. Food Processing Industry and beverage light industry 8. Paper Industry 9. Farm Implement 10. Mining & Metals Processing Industries 11. Transportation 12.Sport and amusement industry 13. Medicine Field |

Why Choose US?

1.Professional manufacturing experience.

2.Virgin 100% material produced, high quality with good surface and color make ensured

3.ISO 9001:2008 certification.

4.Competitive price, In stock, Fast delivery, and Excellent service.

5.OEM available. Special character is available :According to different requirements with different application, color, size, shape and special specifications can be customized.

Packaging Detail: standard exporting package.

We'll try our best to meet your demand and careful about your request.

Delivery Detail: 15 working days after receiving deposit

We are really the manufacture you are looking for!

1.We have professional sales with rich experience of working to handle each order.

2.We undertand your concern and aim to give the best service.

3.We provide quick responses and fast turn-around times

After-sales service - ABOSN Product Quality is Guaranteed

1.We have Strict QC and make sure every step of processing is for specification compliance.

2.We track our goods from transportation to your sales in local market to help your successful business.

3.Manufactured in ISO 9001:2008 facility with over 20 years of manufacturing and fabricating experience.

If you break a pad under normal conditions, Abosn will replace it free of charge.

Established in 1989,Abosn has become the largest manufacture. Our factory covers an area of nearly 50000 square meters, and has 5 workshops for manufacturing 5000 tons every year, including 3000 tons imported to North America, South America, Europe, Africa and other countries of Asia. Our UHMWPE products are mainly including UHMWPE sheet ,UHMWPE rod ,UHMWPE strip, UHMWPE block , UHMWPE fender facing pads , UHMWPE bearing , UHMWPE cutting boards , UHMWPE suction box cover , UHMWPE chain guides , UHMWPE machining block , UHMWPE conveyor impact bar and other UHMWPE machined parts with all kinds of grades and colour .Other PP, PVC, PTFE products can also be provided, and all have passed the latest ISO9001:2008 quality system.

Our UHMWPE products are widely used in North,America,Europe ,Australia,Southeast Asia,Africa,Russia and many other plates around the world due to their outstanding properties .Abosn UHMWPE products have the most type and grades compared to other manufactures.

We manufacture all of our UHMWPE products according with ISO9001:2008 production standards.Our raw material are provided by Ticona which is famous all over the world. We have 16 sets different size of hydraulic pressing machines for pressing UHMWPE sheets ,two extruded machines for UHMWPE Rods ,7sets world two head CNC machines for UHMWPE parts.

Our R&D and new production base was completed in 2014,which greatly increases our manufacturing capabilities.The factory covers 48,000 square meters and features six large scales workshops.We have become China’s largest UHMWPE manufacture with annual production output of 6000000 tons .

Basic Information

Business Type: Manufacturer, Trading Company

Main Products: UHMWPE sheet, UHMWPE rod, UHMNWPE strip, UHMWPE block, UHMWPE facing pads,UHMWPE chain guides,UHMWPE bearing,UHMWPE cutting boards,UHMWPE suction box cover,UHMWPE machining block,UHMWEP conveyor impact bar and other UHMWPE machined parts with all kinds of grades and color. Other PP, PVC, PTFE products can also be provided,and all have passed the latest ISO9001:2008 quality system.

Trade&Market

Main Markets:

- North America

- South America

- Europe

- Africa

- Russia

- Australia

- Southeast Asia

Annual Sales: 6,000,000 tons

Factory Information

Factory Size: Nearly 50,000 square meters

Number of Workshops: 5

Certification: ISO9001:2008

1. When can I get the price?

We usually quote within 24 hours after we get your inquiry.

If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2.How can I get a sample to check your quality?

You can require for samples to check our quality.We will provide you sample for free, as long as you afford the express freight.

3.How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 7~10 working days. The samples will be sent to you via express and arrive in 3-5 days. You can use your own express account or prepay us if you do not have an account.

4.What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, production lead time is within 2~4 weeks.

5.About Price: could I get your price list?

Yes,please tell us the products (with their model number), quantity you are interested in, then we will offer the price by e-mail.

If you have any interest contact us! We will give you the best products and the best service.

Wear resistance UHMWPE roller chain guide

Sold By

Qingdao Abosn was located in Qingdao, the third-largest port city in China; with convenient traffic and developed imports and exports. As the qingdao...

Contact Seller

MessageBuyer Protection

-Secure payments

-Guaranteed refunds

-Escrow protection on every order

-Guaranteed delivery of goods

Product Groups

- Ungrouped

- UHMWPE Fender facing pads

- UHMWPE Liner sheet

- UHMWPE Wear resisting strip

- UHMWPE Dewatering elements

- UHMWPE Dock bumper

- Crane Outrigger Pads

- UHMWPE Chain guides

- UHMWPE Rod

- PTFE Sheet

- UHMWPE Sheet

- Ground protection mat

- PP sheet

- Conveyor impact bar

- Cutting Board

- Ice Rink System

- PVC

- Other UHMWPE machined parts

- HDPE Sheet

- More

鲁公网安备37079102000201号

鲁公网安备37079102000201号