1

Basic Info

- Place of Origin:

- Brand Name:

- Model Number:

- Material:

- Thickness:

- Size:

- Density:

- Molecular Weight:

- Elongation at break:

- Tensile strength:

- Coefficient of friction:

- Color:

- Certificate:

- size:

- thickness:

Product Description

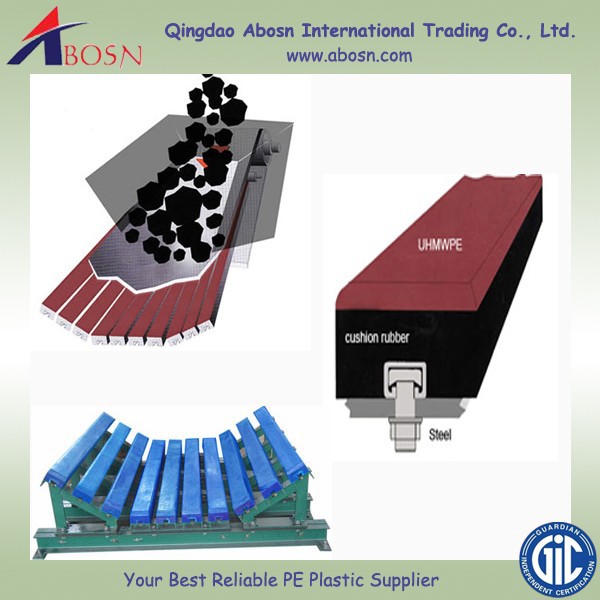

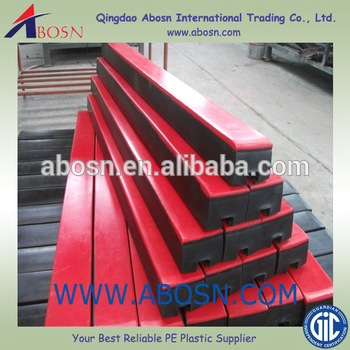

conveyor supporting impact bar/uhmwpe impact bar

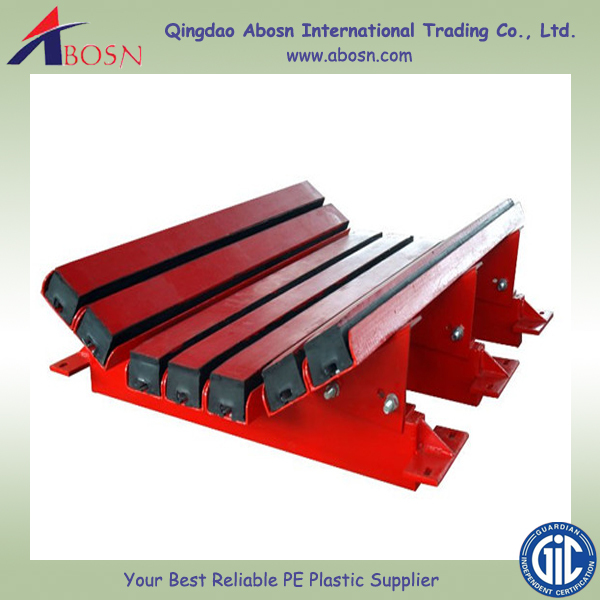

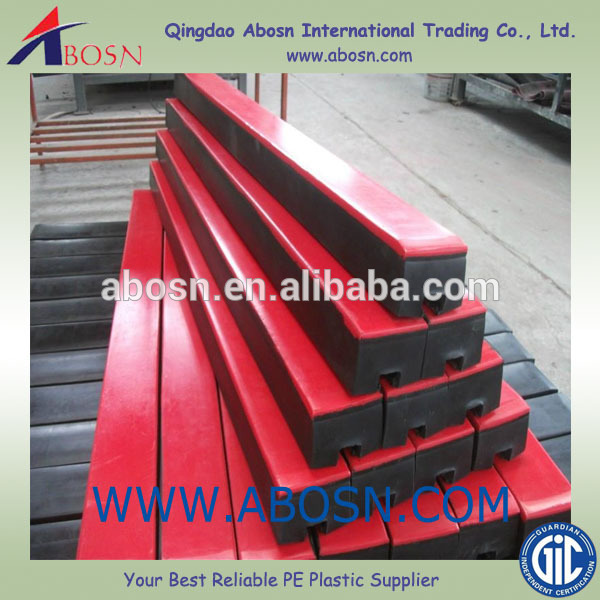

Top grade top sell impact bed bar buffer strip Used in the conveyor loading points or transfer points to replace traditional cushion rollers. It’s designed to absorb impact loading and help eliminate spillage and scattering of the products. This results in less wear and tear on your conveyor system, dramatically improves the efficiency and reduces the maintenance cost.

Features:

1.Avoids the damage to the belt through the contact between the bar and surface of belt.

2.The conveyor belt is stressed evenly in the loading area, which will reduce the daily maintenance cost.

3.Effectively eliminate the spillage or scattering of the material caused by unequality of the stress on the belt.

4.The UHMW polyethylene surface has outstanding sliding properties.

5.Arc surface of polyethylene enables the conveyor belt to running smoothly.

6.Ultra elastic rubber absorb the impact in the maximum.

7.Each part of the impact bar is closely jointed by hot vulcanization. Fastening device has different tightening points along the bar and make the joining strong and reliable, easy to install and remove.

The loading zone of a conveyor is a critical area from maintenance and spillage point of view. The type and size of material as well as height of drop are the main factors causing damage not only to belt but also the rubber rings and bearings of the conventional impact idler rolls. All of these lead to seizure and breakdown of impact rolls, meaning severe downtime problems

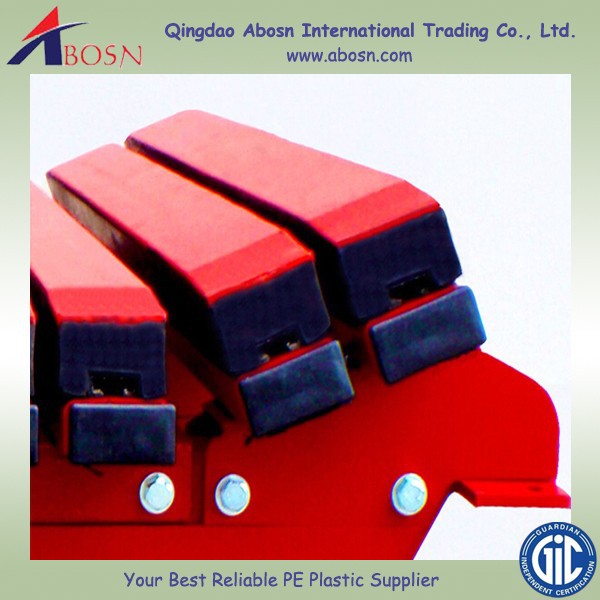

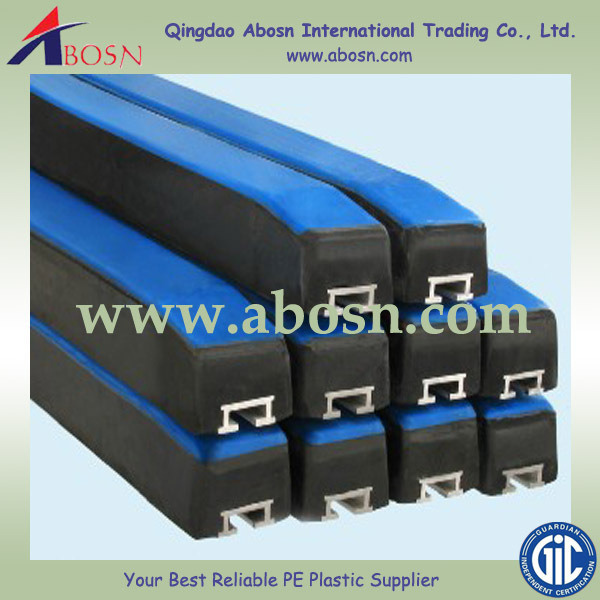

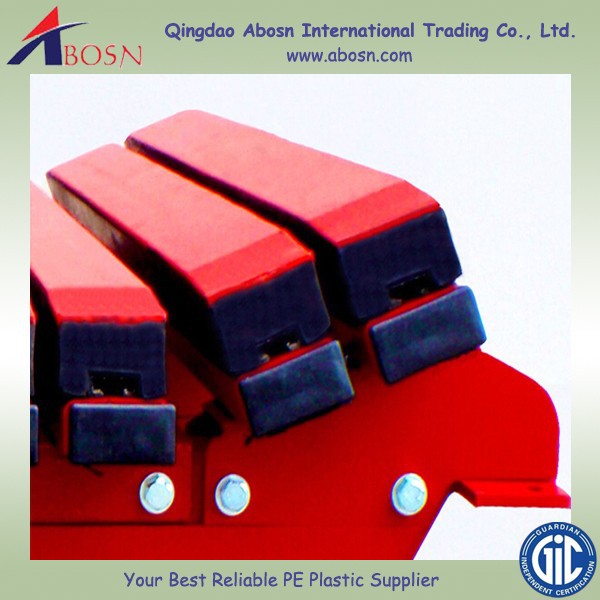

The impact bar is a combination of three different layers. The top layer is made of UHMWPE for smooth movement of belt, thanks to its low dynamic co-efficient of friction. The middle layer is of rubber to cushion the impact load while the

lower layer is made of aluminum, which acts as a fastening device with the main support frame or cradle. The cradlers are custom built to suit specific applications. The installation of impact bar is made is such a way that the belt is not in touch with the bar when running empty. The belt comes in contact with the bar only when it is running under loaded condition.

Advantages:

1. Avoids the dage to the belt through the contact between the bar and surface of belt.

2.The conveyor belt is stressed evenly in the loading area, which will reduce the daily maintenance cost. It effectively eliminates the spillage or scattering of the material causedby inequality of the stress on the belt.

3.The UHMW polyethylene surface has outstanding sliding properties,to reduce the frictional resistance to the minimum.

4. Ultra elastic rubber absorbs the impact in the maximum.

5. Each part of the impact bar is closely jointed by hot vulcanization.

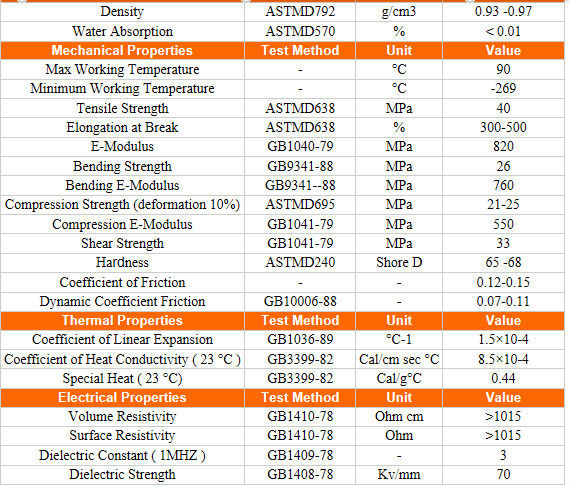

Technical parameter:

1,Material of surface of impact bar: UHMW

2,Tensile strength: >25N/mm2

3,Elongation:> 350%

4, Impact strength: >10kJ/m2

5, Speeling stength: UHMW and Rubber>200N/cm

Rubber and aluminum frame >200N/cm

1,Impact rubber of impact bar

2,Tensile strength:> 15N/mm2

3,Elongation:> 400%

4,Hardness:Shore A 35~40

5,Framework of impact bar: Aluminum

6,Impact bar stand:Q235A;painting surface

Main Properties:

Excellent Abrasion-resistance

Good self-lubrication and low coefficient of friction

High anti-impact strength and good toughness

Good chemical corrosion resistance can resist almost all mediums such as

acid,alcli and salt,but except for concen trated sul-phuric-acid,concentrated

nitric and a few organic solvents.

Inodorous,in noxious and impenetrable

Good conductibility and ultra-low water absorbability

Good anti-environmental stress breakage property which is 200 times of ordinary

ethylene

Good cold resistance property which isnit brittle even if at 176°Cbeiow zero.

Item | Test method | Test result | unit |

Specific weight | ASTM D-792 | 0.93-0.95 | g/cm3 |

Yield strength | ASTM D-638 | 25 | MPa |

Ultimate strength | ASTM D-638 | 45 | MPa |

Breaking Elongation | ISO527 | 355 | % |

Impact strength | ISO179 | 130 | Mj/mm2 |

Abrasion | ISO15527 | 83 | Steel=100 |

Shore Hardness | ISO868 | 65 | Shore D |

Friction Coefficient | ASTM D-1894 | 0.11 | Unitless |

Coefficient of thermal expansion | ASTM D-696 | 0.0002 | ℃ |

Volume resistifity | IEC600093 | ≤1000 | ∩*cm |

Surface resistifity | IEC600093 | ≤1000 | ∩ |

Water Absorption | ASTM D-570 | 0.0094 | % |

Melt point | ASTM D-3417 | 138 | ℃ |

- Specification:

Packing | Plastic Film, Pallet, Wooden Box, Carton, etc. |

Shipping | International Express (DHL, UPS, FEDEX, EMS, etc.), Ocean Transport, Air Transport |

We focus on what our customers need and dedicate to produce satisfying products and innovate new products to our clients.

After-sales service - ABOSN Product Quality is Guaranteed

- We have Strict QC and make sure every step of processing is for specification compliance.

- We track our goods from transportation to your sales in local market to help your successful business.

- Manufactured in ISO 9001:2008 facility with over 20 years of manufacturing and fabricating experience.

- If you break a pad under normal conditions, Abosn will replace it free of charge

Our Abosn company:

- Mainly manufacture HDPE and UHMWPE products.

- Have rich experience in the line of engineer plastic products for long time.

- Passed the latest ISO9001:2008 quality system.

- Located in Qingdao, the third-largest port city in China.

- Convenient traffic and developed imports and exports.

Q:Is the size fixed?

A:No.we can meet your needs according to your acquirement. That is to say, we accept to customize.

Q: What is your MOQ of this item?

A: 500 kilograms.

Q: Is it all right to make customer's own brand name?

A: That’s all right to engrave your own brand name.

Q: What is your company's available production capacity?

A: Usually 9000 tonnes per year.

Q. Can you special order a product for me?

A. We are typically able to special order products for customers. OEM service

If any questions,please feel free to contact us anytime

conveyor supporting impact bar/uhmwpe impact bar

Sold By

Qingdao Abosn was located in Qingdao, the third-largest port city in China; with convenient traffic and developed imports and exports. As the qingdao...

Contact Seller

MessageBuyer Protection

-Secure payments

-Guaranteed refunds

-Escrow protection on every order

-Guaranteed delivery of goods

Product Groups

- Ungrouped

- UHMWPE Fender facing pads

- UHMWPE Liner sheet

- UHMWPE Wear resisting strip

- UHMWPE Dewatering elements

- UHMWPE Dock bumper

- Crane Outrigger Pads

- UHMWPE Chain guides

- UHMWPE Rod

- PTFE Sheet

- UHMWPE Sheet

- Ground protection mat

- PP sheet

- Conveyor impact bar

- Cutting Board

- Ice Rink System

- PVC

- Other UHMWPE machined parts

- HDPE Sheet

- More

鲁公网安备37079102000201号

鲁公网安备37079102000201号