Basic Info

- Driven Type:

- Classification:

- Application:

- Automatic Grade:

- Membrane Material:

- Plastic Film Mulching Modes:

- Paper Size:

- Performance:

- HS Code:

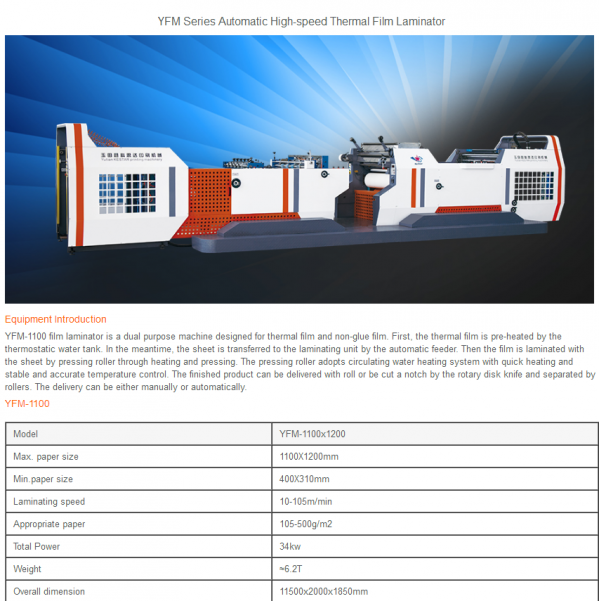

Product Description

YFM-1100 film laminator is a dual purpose machine designed for thermal film and non-glue film. First, the thermal film is pre-heated by the thermostatic water tank. In the meantime, the sheet is transferred to the laminating unit by the automatic feeder. Then the film is laminated with the sheet by pressing roller through heating and pressing. The pressing roller adopts circulating water heating system with quick heating and stable and accurate temperature control. The finished product can be delivered with roll or be cut a notch by the rotary disk knife and separated by rollers. The delivery can be either manually or automatically.

●The feeder is equipped with pre-loading devices, which allows feeding paper without stopping the machine.

●The powder removal device adopts hot-pressing static mechanism, sticking powder and pre-heating the paper, thus enables the machine to run at a high speed.

●The laminating roller adopts double layer spiral waterway design, which makes the roller fast in temperature rising and higher heat efficiency and the isothermal error of the roller is less than 2℃ under a high speed running.

●The electronic integrated thermal water circulating system and heat recycling enhances laminating speed and laminating quality, and greatly reduces the energy consumption.

●The pressing unit uses hydraulic station for automatic buck-boost and pressure compensation.

●Equipped with pneumatic shaft and film lifting device, it is easy for film loading.

●Automatic film- tension- control system ensures smooth film feeding.

●Two delivery shafts are available for customers to choose roll delivery or directly separating.

●The separator is equipped with a flatten device for thinner paper, it is cooperated with the tension adjustor for paper flatness.

●Rotary disk knife with pinwheel perforating device ensures high-speed separating.

●The delivery unit uses vacuum suction feeding, which makes more smooth paper transferring.

●Automatic pivoting device allows sheet to be transferred into the manual delivery unit when delivery in trouble.

●The paper bending device used for delivery, enhances the paper deflection.

●Intermittent air flow used under the paper facilitates thinner or warped paper to be delivered quickly.

●The mechanic back jogger and pneumatic side jogger ensures tidy delivery of paper.

Buyer Protection

-Secure payments

-Guaranteed refunds

-Escrow protection on every order

-Guaranteed delivery of goods

鲁公网安备37079102000201号

鲁公网安备37079102000201号