US $50000.00-70000/Set

1 Set

Qingdao or Shanghai or Lianyungang

L/C,D/P,Western Union,Paypal,Money Gram,Others

tyre pyrolysis plant, plastic pyrolysis plant

> Industrial Equipment & Components > Cleaning Machine > Other Cleaning Machines > Waste tyre pyrolysis oil refined to diesel distillation machine US $50000.00-70000/Set

1 Set

Qingdao or Shanghai or Lianyungang

L/C,D/P,Western Union,Paypal,Money Gram,Others

Product Description

Product introduction of Waste tyre pyrolysis oil refined to diesel distillation machine

Waste tyre pyrolysis oil refined to diesel distillation machine can process waste engine oil, used motor oil, black oil, tire oil, plastic oil to clean diesel. This kind of diesel can be used to tractors, trucks, diesel oil generator, power generator etc. Oil recovery average rate: 85%-95%. Unique design and outstanding functions can help customer create more profit. This equipment is matched with pyrolysis plant. It is widely applied in waste oil management industry.

Technical parameter of Waste tyre pyrolysis oil refined to diesel distillation machine

Items | Contents |

Model | DY-5T, DY-10T, DY-15T, DY- 20T... |

Raw material | used motor oil, waste engine oil, tire pyrolysis oil, plastic pyrolysis oil |

Structure form | Vertical (easy cleaning and maintenance) |

Heating method | Indirect heating to prolong the machine service life |

Operating pressure | Constant pressure |

Heating material | Coal, charcoal, fuel gas, fuel oil |

Average out-put oil rate | 95% |

Material of reactor | 4 reactor with different material |

Thickness of reactor | 18mm |

Mode of cooling | Recycled water cooling |

Power in total | 20 Kw |

Service life | average 7 years |

Land area | 180 square meters |

The working process of Waste tyre pyrolysis oil refined to diesel distillation machine

1. Heat the heat conduction oil with the heat conduction oil furnace;

2. The heat conducting oil flows into the coil in the distillation reactor and heats the waste engine oil in the distillation reactor;

3. When the waste engine oil is heated to a certain temperature, the reactor is directly heated with fuel. As the temperature increases, the waste engine oil produces oil and flows into the buffer tank. The odorous light components in the waste engine oil can be distilled and collected into the distillation tank.

4. The oil gas from the buffer tank enters the catalytic tower. In the catalytic tower the macromolecular oil gas are broken down into smaller molecules .

5. Oil gas of small molecules enter the cooling system through the catalytic tower and are cooled into liquid oil;

6. After the oil gas steam out, the distillation reactor memory has plenty of hot asphalt, which can be extracted by the asphalt pump.

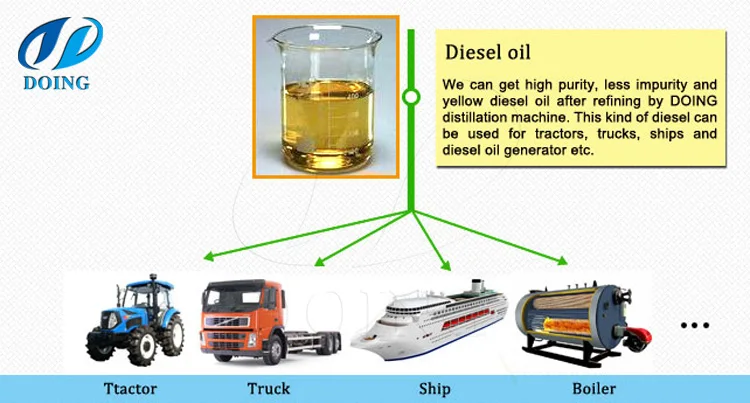

The products of Waste tyre pyrolysis oil refined to diesel distillation machine

Two products can be obtained from the Waste tyre pyrolysis oil refined to diesel distillation machine, 80%-85% diesel, 15%-25% asphalt. For the 80-85% diesel oil, you can used it into heavy machinery, gernerator, and boiler. For the 15%-25% asphalt, could be used for paving, or directly sold to asphalt refineries for further refining.

The unique advantages of DOING Waste tyre pyrolysis oil refined to diesel distillation machine

Safety:

Safety is the most important factor in the whole process. We had successfully researched some safety devices which ensure Waste tyre pyrolysis oil refined to diesel distillation machine work safely.

1. Safety valves, alarming device and the pressure gauge etc.

2. We also have oil-water separator which can stop the oil gas recycle to the reactor, which could avoid the accident.

3. High degree of automation: feed the waste oil, crude oil automatically, to pump oil automatically.

Energy saving:

1. Well sealing for heating system, no gas leak and saving fuel.

2. Continuous feeding with automatic feeder, no gas leak.

3. Recycling of exhaust gas and scientific fire channel design can save energy and thereby reducing costs.

Environmental friendly:

1. The whole process is all sealed, won't release any gas harmful to human and environment.

2. Well water dedusting system can avoid black smoke.

Packaging & Shipping

The packaging &shipping of Waste tyre pyrolysis oil refined to diesel distillation machine

Project case of Waste tyre pyrolysis oil refined to diesel distillation machine

With mature production technology and professional sales, engineers and installation team, through the unremitting technological innovation and following the market demand, we have installed machines in more than 60 countries around the world, including:

Asia: China, Bangladesh, Malaysia, Pakistan, India, Thailand, Philippines

Mid-east: Lebanon, Jordan, Palestine, United Arab Emirates, Saudi Arabia, Iran

Africa: South Africa, Egypt, Nigeria, Kenya, Congo, Uganda, Serbia, Senegal, Cameroon, Kenya, Liberia, Algeria, Ethiopia

Americas: Columbia, Panama, Mexico, Jamaica, Chile, Guatemala, Ecuador, Aruba, Haiti, Argentina, Canada

Europe: Romania, Italy, Czech Republic, Estonia, Macedonia, Poland, Turkey, France, Albania, Georgia

Oceania: Australia, etc

Our Services

After-sales service of Waste tyre pyrolysis oil refined to diesel distillation machine

1. Delivery time

It will be 10-15 days after we receive the deposit.

2. Warranty

The warranty period for reactor and other parts except spare parts is 1 year. The problem caused by wrong operation of workers shall not be responsible by our company.

3. Installation and Training

Our company will send one technician for each set of machine for guiding your installation, testing the machine and training your worker.

We have a professional customer service process to ensure customers' satisfaction from contact us to machine installation and after-sale service. If you have any question about the Waste tyre pyrolysis oil refined to diesel distillation machine, please contact us in time and you will get a satisfactory solution!

Company Information

Henan Doing Machinery Equipment Co., Ltd. has been dedicated to the research and development of large and medium-sized renewable energy environmental protection equipment and a variety of waste recycling equipment for years. We are professional manufacturing enterprise which gather development, design, production, sales, installation and after-sales service in one. DOING's business scope involves waste tire/plastic/rubber pyrolysis equipment, waste oil to diesel fuel refinery.

DOING's office headquarters is in Zhengdong New District of Zhengzhou City, and DOING's manufacturing factories are located in Xinxiang and Jiaozuo city, the factory covers an area of over 40,000 square meters.

Website: www.china-doing.com

whatsapp/wechat: +86 13526692320

Email:sales@china-doing.com

DOING is a professional manufacturing enterprise which gather development, design, production, sales, installation and after-sales service in one. We ...

-Secure payments

-Guaranteed refunds

-Escrow protection on every order

-Guaranteed delivery of goods