1 Set

Qingdao

2tpd

T/T,D/P,Western Union,Money Gram,cash

palm oil processing machine,palm kernel oil expeller machine,palm oil making machine,palm oil press machine,palm kernel oil making machine,palm oil refining machine ,palm kernel oil refining machine,palm oil fractionation plant

> Manufacturing & Processing Machinery > Agricultural Machinery > Oil Pressers > 2tpd small scale palm oil refining machine for sale 1 Set

Qingdao

2tpd

T/T,D/P,Western Union,Money Gram,cash

Palm oil refining machine introduction:

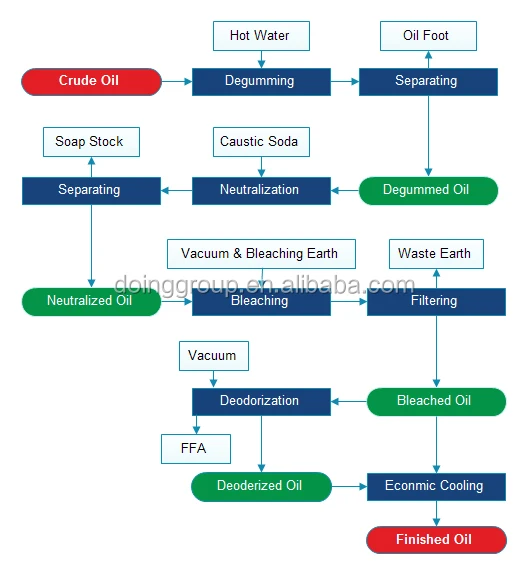

Refining is a process to remove unwanted and undesirable elements from the crude edible oil. Palm oil refining machine usually includes the following sections: Degumming,Deacidification, Decolorization, and Deodorization.

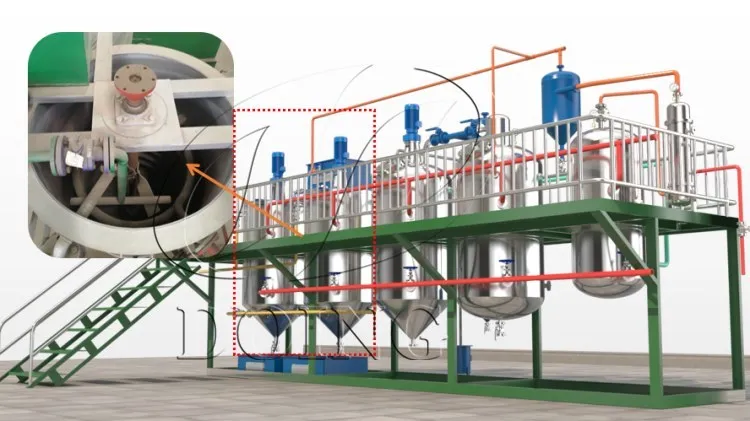

Our palm oil refining machine adopts the most advanced CE and ISO9001 approval edible oil refining line to get high purity and high oil yield refined palm oil. Available with both physical and chemical refinery technology, we are able to provide customers the most affordable palm oil refining machine including design, manufacturing, installation with guaranteed quality and reliable service.

Degumming process of palm oil refining machine:

Intermittent process preheats crude palm oil to 80 ~ 85 ℃. The amount of water in crude oil bases on colloid content, and generally 3-5 times of the gum content, water temperature at 85 ~ 90 ℃ (5 ℃ higher than oil temperature). Finish water adding in 40-60min, along with 60-70r/min stirring, continue stirring 3-5min after adding water, and stand for precipitation 2-4h.

Deacidification process of palm oil refining machine:

The crude palm oil is pumped to Deacidification from oil mill or storage tank & first it is treated with weak solution of phosphoric acid or other suitable degumming agent for removing gums. Deacidification is used remove the Free Fatty Acids (FFA) by adding caustic soda. Oil is heated up to about 60°C by heating coils and oil is stirred by the stirrer. The chemical reaction between free fatty acid and caustic soda forms the soap stock. This soap stock is allowed to settle down in the neutralizer from where it is collected into the soap pans. The oil is then washed with hot water to remove traces of soap particles and free alkali.

Decolorization process of palm oil refining machine:

Degumming of palm oil can remove grease in oil pigment to improve oil color, adsorption of aflatoxin and trace metals, phospholipids, other gum and other impurities. It ensures high quality of palm oil and improves oil stability.

Deodorization process of vegetable oil refining machine.

Control oil temperature to 250 ~ 270 ℃ when decolorized corn germ oil enters into deodorizer, in direct steam injection, the free fatty acids, ketones, aldehydes and other impurities are removed from the oil, the thermal decolorized action also occurs, and the pigment composition is cleaved distilled from the oil. Deodorized vacuum (absolute pressure) controlled at 266 Pa, the deodorization time is about 2h.

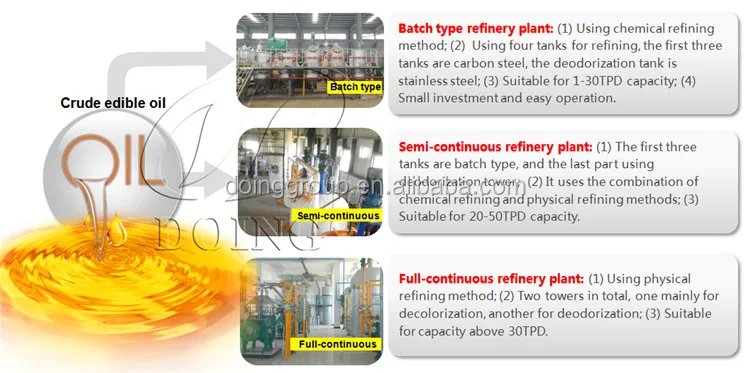

Available capacity for vegetable palm oil refining machine are as follows:

1-2-3-5-10TPD batch type cooking palm oil refinery machine;

10-15-20-25-30-50TPD semi continuous cooking palm oil refinery machine;

50-80-100-150-300-600TPD full continuous cooking palm oil refinery machine;

Contact information:

http://www.palmoilextractionmachine.com

http://www.palmoilprocessingmachine.com

whatsapp/wechat: +86 13526627860

Email: palmoil@doingmachinery.com

Henan Doing Machinery Equipment Co., Ltd. has been dedicated to the research and development of large, medium-sized and small -sized palm oil processi...

-Secure payments

-Guaranteed refunds

-Escrow protection on every order

-Guaranteed delivery of goods