US $76000.00-120000/Piece

1 Piece

ningbo

30sets/month

L/C,Western Union,Paypal,Money Gram,Others

extrusion coating and lamination machine,paper poly coating machine,pe film extrusion coating machine,nonwoven pp film extrusion lamination machine,alu foil extrusion lamination machine,paper slitter and rewinder,paper cutter and sheeter

> Manufacturing & Processing Machinery > Paper Machinery > Other Paper Machinery > Yilian brand SJFM1300A paper poly coating machine US $76000.00-120000/Piece

1 Piece

ningbo

30sets/month

L/C,Western Union,Paypal,Money Gram,Others

Application:

cup paper,shopping bag paper, fast food boxes,cement chemicals packing, food packing paper, medicine packing paper, and other packaging materials.

Technical Parameter

1.Applicable coating film resin: Coating grade like LDPE 、PP 、EVA、EAA etc .

2.Based material: paper (35~425g/m2 )

3.Max working speed: 100~150m/min

4.Min./ Max width of coating film: 500mm-1250mm

5.Thickness of coating film: 0.01–0.11mm

6.Inaccuracy thickness of coating film: ±5%

7.Setting range of Auto-tension : 20-400kg/entire width (constant tension)

8.Max extrusion: 200kg/h

9.Compound cooling roller: Φ508×1300mm (can choose)

10. Total power:about 110kw

11.Working power:60kw-80kw

12.Max rewinding diameter: Φ1300mm

13. Inside diameter of base material: Φ76

14.Machine total weight: about 15000kg

15.Overall dimension:9600mm×8000×3250mm(L×W×H)

16.Machine color: can choose

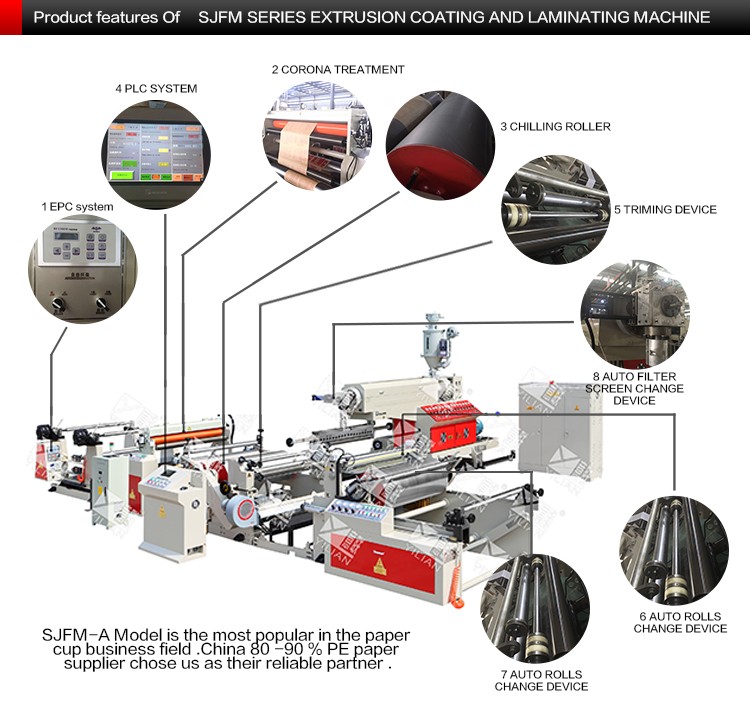

Features:

1.Double stations of non-stop feeding system, pre-drive high speed paper changing system, intermediate floating straight edge system, automatic tension control, according to the sensor to detect, feedback, automatically adjust the tension, realize the whole machine line tension automatically control.

2.Cooling roller adopts high degree of finish roller, which can eliminate bubbles produced during the compounding process.

3.Silicone roller and cooling roller adopt screw-type cooling structure, which to make cooling quickly and laminating easily.

4.Rotary type water joints adopts domestic advanced seal structure ,to prevent leaking and prolong life of joints

5.Compounding roller is droved by one vector frequency electric motor, can adjust the speed quickly ,to making different thickness of the film what we need, Ensure the thickness uniformity the same.

6.T-type flow structure, the key parts (die lip) to facilitate flexible adjustments plated lapping processed to ensure that the effect of the lamination was smooth.

7.The domestic leading of automatic hydraulic changing filter device ,is able to filtering impurities ,cutting molten resin quickly when machine stopped,reduce waste of resin.

8.large length to diameter ratio, the resin more thoroughly when the winding is not easy crimping.

9.The machine adopts PLC One-touch centralized controls,advanced touch screen control system.

10.It controls the speed of the extruder and compounding body at the same time, the extruder along with the compounding body to higher speed, lower speed, and proportional increasing or decreasing, assure film thickness is constant

11.According to requirements , set coating film thickness, the extruder can cooperate compounding body speed automatically, to reach setted the film thickness.

12.Multi-parameter memory function, feel free to call stored in the parameters system.

13.Tension, speed and working condition are dynamic display

Wenzhou Winrich Machinery Co.,ltd is located in Pingyang county,Wenzhou city of Zhejiang Province,China, established in 1996. It covers land area of 1...

-Secure payments

-Guaranteed refunds

-Escrow protection on every order

-Guaranteed delivery of goods